- By mougen

- 28 Feb 2025

- No Comments

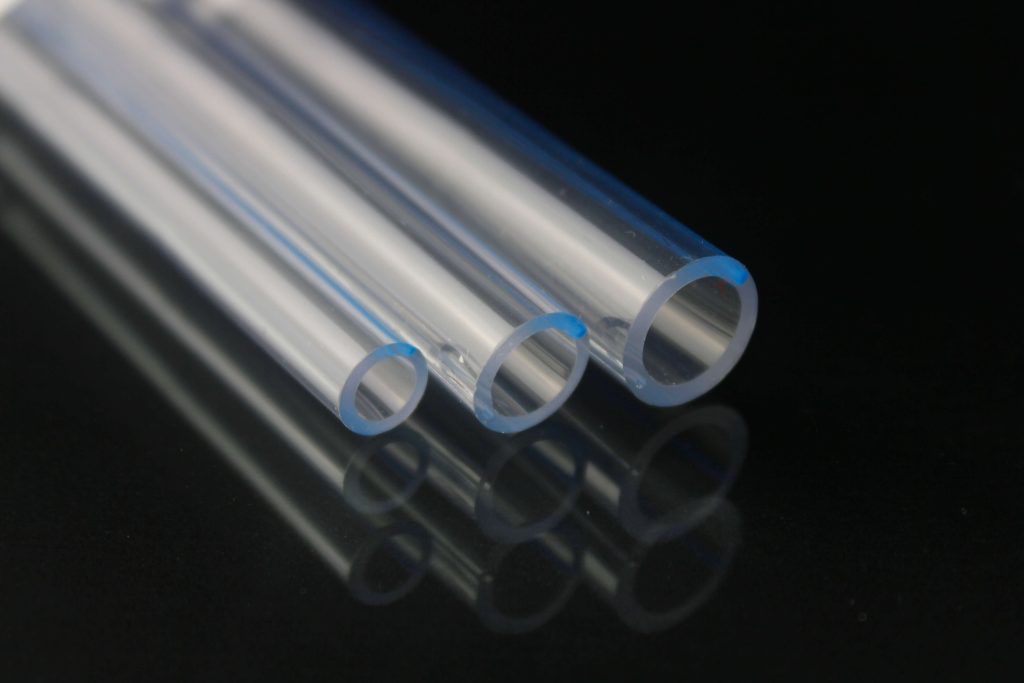

PPR is the abbreviation for polypropylene tubing, also known as random copolymer polypropylene tubing. It is hot-melt welded and has specialized welding and cutting tools, and has high plasticity. The price is also very economical. The insulation performance is also very good, and the pipe wall is very smooth. The general price is 6-12 yuan per meter (4 pipes), excluding the joints of the inner and outer wires. Generally used for embedded walls or deep well pre embedded pipes.

PPR pipes are moderately priced, stable in performance, heat-resistant and corrosion-resistant, with smooth and non scaling inner walls. The pipeline system is safe and reliable, and does not penetrate, with a service life of up to 50 years. But the construction technology requires high standards, and specialized tools and personnel are needed for construction to ensure system safety.

Six advantages of PPR composite pipe production line

1. The production line adopts PLC control system, with high degree of automation and simple and convenient operation;

2. Accurate synchronous control technology ensures that the operating speed of each traction machine is balanced and consistent.

3. The use of outer tube co extrusion technology has improved the interlayer bonding strength of the pipe material.

4. Equipped with internationally renowned brand argon arc welding machine and welding gun cooling device, it can ensure the long-term continuous production.

5. The PPR composite pipe production line has the advantages of high pressure resistance, high temperature resistance, and non separation of aluminum-plastic materials.